Please observe that we've a massive stock on hand for fast transport comfort for our purchaser with transparent price, so you can order directly through contacting us at jinanbote@126.com.cn .Description Diameter× Height (mm×mm)Wall Thickness (mm)Max Vol (ml)MarkTC1260¢12X601.05TC1660¢16X602.06TC1818¢18X180.83TC19100¢19X1001.510Arc bottomTC3030¢30×301.815TC3060¢30×601.830TC3210¢32×101.55TC3585¢35×8.51.55TC3645¢36×452.530TC4032¢40×321.630Description Diameter× Height &n

Contact Now

Alumina crucibles are synthetic for extra than 20 years and have a skill manufacturing era in specific shapes and range of sizes from few milliliters to several liters, those absolutely dense, excessive purity and subjected to a temperature of 1700 ℃ , offering resistance in opposition to wear, wash, excessive temperature, has excellent resistance to chemical erosions and thermal shock. together with metallic processing / molten glass, rapid thermal biking, gemstone purification for jewelry industry etc.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a superb thermal marvel at tempertures to 2000℃, higher corrosion proof towards acids and alkalis ,widely applied in superalloy and treasured metals industries, at the side of induction melting crucibles for expert steel, glass melting, precious and extraordinary metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the use o

Contact Now

We've got correctly supplied many special formed merchandise appropriate for the multitudinous customers, espically awareness on researches on small-sizes and complex form alumina components. we promise a committed non-public provider at low rate, the manufacturing cycle is short, nimble, quickly. no minimal order fee.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

We've got had been given correctly provided many unique formed products appropriate for the multitudinous customers, espically attention on researches on small-sizes and complex shape alumina components. we promise a committed non-public agency at low fee, the producing cycle is brief, nimble, brief. no minimum order charge. SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

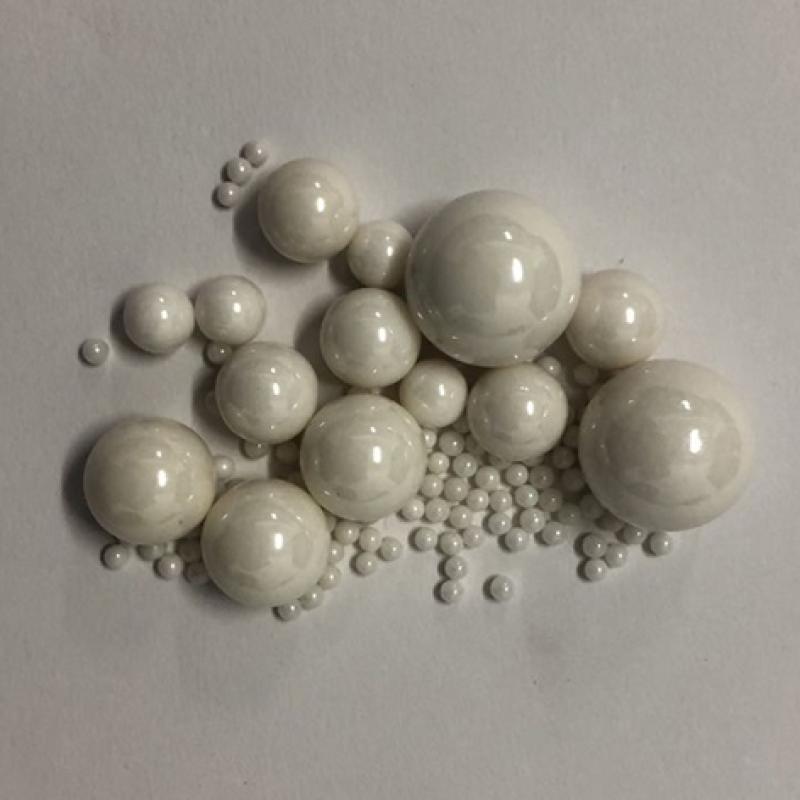

Alumina porcelain balls via the medical formulation, the medical sorting tool ensures the maximum useful roundness, the floor of the sector is simple, , low placed on inside the grinding situations, is a notable grinding medium, excessive hardness, corrosion resistance, effect resistance, monetary and practical, pollutants-unfastened ,is extensively implemented in particular forms of ceramics, porcelain glaze, glass, chemical and different factories, especially using ninety content material of excessive alumina balls is the most not unusual, but also the producing of ninety nine% of high

Contact Now

Alumina porcelain balls thru the medical formulation, the scientific sorting system guarantees the optimal roundness, the floor of the field is easy, , low wear inside the grinding situations, is a first rate grinding medium, high hardness, corrosion resistance, effect resistance, economic and sensible, pollutants-free ,is widely utilized in special forms of ceramics, porcelain glaze, glass, chemical and other factories, specifically using ninety two content of high alumina balls is the most not unusual, however also the manufacturing of 99% of high purity balls.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a very good thermal surprise at tempertures to 2000℃, higher corrosion proof against acids and alkalis ,widely utilized in superalloy and valuable metals industries, which include induction melting crucibles for specialist metal, glass melting, treasured and different metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the

Contact Now

Crucibles serve as containers for samples during thermoanalytical measurements.

Contact Now

Zirconia products is in yttria stabilised zirconia. They are either refractory porous crucibles or Zirconia ceramic crucibles.

Contact Now

Please examine that we've got a massive inventory on hand for fast delivery consolation for our patron with obvious charge, so you can order at once through contacting us at jinanbote@126.com.cn . SpecificationSpecidimater(mm)High (mm)volume (μl)Compitable with Mettler Part noBTTA602662.630ME-51140843BTTA604564.570ME-00024123BTTA804584.5150ME-00024124BTTA12101210900ME-51119960Material:99.5% High purity alumina Specifications;:BTTA-4570 Size:¢4.5X7.0 Wall thicknes

Contact Now

We've got correctly provided many special shaped merchandise suitable for the multitudinous customers, espically consciousness on researches on small-sizes and complicated form alumina elements. we promise a dedicated private provider at low fee, the production cycle is short, nimble, fast. no minimum order cost.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a very good thermal shock at tempertures to 2000℃, better corrosion resistant to acids and alkalis ,widely used in superalloy and precious metals industries, such as induction melting crucibles for specialist steel, glass melting, precious and other metals melting. Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the use of t

Contact Now

Alumina porcelain balls thru the clinical formula, the clinical sorting device ensures the most beneficial roundness, the ground of the sector is easy, , low located on within the grinding situations, is a super grinding medium, immoderate hardness, corrosion resistance, impact resistance, monetary and sensible, pollution-unfastened ,is substantially implemented specially sorts of ceramics, porcelain glaze, glass, chemical and specific factories, in particular the usage of 90 content cloth of excessive alumina balls is the maximum not unusual, however also the manufacturing of 99% of hig

Contact Now

The grinding ball of ceramic is a large range of applications of inorganic non-metallic grinding medium, specially utilized in grinding and dispersion of important regions, our organisation specifically produces grinding with zirconium balls, especially worried inside the sand mill interior, dispersion is mainly concerned in high-pace blending mill interior.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a very good thermal shock at tempertures to 2000℃, better corrosion resistant to acids and alkalis ,widely used in superalloy and precious metals industries, such as induction melting crucibles for specialist steel, glass melting, precious and other metals melting. Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the use of t

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a very good thermal surprise at tempertures to 2000℃, higher corrosion proof against acids and alkalis ,broadly utilized in superalloy and treasured metals industries, along with induction melting crucibles for specialist steel, glass melting, precious and different metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the us

Contact Now

Alumina porcelain balls thru the medical formula, the medical sorting device guarantees the most useful roundness, the ground of the sector is easy, , low put on within the grinding situations, is a brilliant grinding medium, high hardness, corrosion resistance, effect resistance, economic and sensible, pollution-unfastened ,is broadly applied in unique varieties of ceramics, porcelain glaze, glass, chemical and other factories, particularly the usage of 90 content of high alumina balls is the most common, but also the producing of ninety nine% of high purity balls.

Contact Now

Crucibles feature bins for samples sooner or later of thermoanalytical measurements.

Contact Now

Zirconia porcelain ball is a huge kind of applications of inorganic non-steel grinding medium, especially accomplished in grinding and dispersion of most vital areas, our business enterprise enterprise business enterprise mainly produces grinding with zirconium balls, mainly involved inside the sand mill inner, dispersion is specially concerned in excessive-tempo blending mill inner.

Contact Now

We have successfully provided many special shaped products suitable for the multitudinous customers, espically focus on researches on small-sizes and complex shape alumina parts. We promise a dedicated personal service at low price, The production cycle is short, nimble, quickly. no minimum order value.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

We have were given have been given effectively provided many specific shaped products appropriate for the multitudinous clients, espically reputation on researches on small-sizes and complex shape alumina factors. we promise a dedicated private company at low rate, the manufacturing cycle is brief, nimble, speedy. no minimum order cost.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

We've had been given have been given were given successfully furnished many precise usual products appropriate for the multitudinous customers, espically interest on researches on small-sizes and complex shape alumina components. we promise a committed personal company at low rate, the manufacturing cycle is short, nimble, brief. no minimum order charge. SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

Magnesia(MgO)crucibles can withstand the high temperature up to 2200°C and has very good resistance to chemical erosions and thermal shock. There is ideal for the melting of precious metals and super-alloys. They possess higher refractory (up to 2000℃ )compared to alumina ceramics , better corrosion resistant to acids and alkalis ,better abrasion resistance. They exhibit fully dense, high strength, extreme wear resistant.

Contact Now