Platinum alloy crucibleare manufactured for greater than two decades and feature a talent production generation in distinct shapes and range of sizes from few milliliters to numerous liters, these completely dense, excessive purity and subjected to a temperature of 1700 ℃ , providing resistance in opposition to put on, wash, high temperature, has very good resistance to chemical erosions and thermal surprise. consisting of metallic processing / molten glass, fast thermal cycling, gemstone purification for jewelry enterprise and so forth.

Contact Now

Platinum alloy crucibleare manufactured for added than many years and function a talents production era in wonderful shapes and range of sizes from few milliliters to numerous liters, those completely dense, excessive purity and subjected to a temperature of 1700 ℃ , imparting resistance in competition to place on, wash, immoderate temperature, has splendid resistance to chemical erosions and thermal marvel. which encompass metallic processing / molten glass, fast thermal cycling, gemstone purification for earrings business enterprise and so forth.

Contact Now

Platinum alloy crucibleare manufactured for more than 20 years and have a skill production technology in different shapes and range of sizes from few milliliters to several liters, these fully dense, high purity and subjected to a temperature of 1700 ℃ , featuring resistance against wear, wash, high temperature, has very good resistance to chemical erosions and thermal shock.

Contact Now

Platinum alloy crucibleare manufactured for added than many years and function a talents production era in wonderful shapes and range of sizes from few milliliters to numerous liters, those completely dense, excessive purity and subjected to a temperature of 1700 ℃ , imparting resistance in competition to place on, wash, immoderate temperature, has splendid resistance to chemical erosions and thermal marvel. which encompass metallic processing / molten glass, fast thermal cycling, gemstone purification for earrings business enterprise and so forth.

Contact Now

Platinum alloy crucibleare manufactured for extra than many years and feature a skills manufacturing era in distinct shapes and range of sizes from few milliliters to severa liters, those completely dense, excessive purity and subjected to a temperature of 1700 ℃ , presenting resistance in competition to position on, wash, excessive temperature, has excellent resistance to chemical erosions and thermal surprise. which include metallic processing / molten glass, speedy thermal cycling, gemstone purification for jewelry agency and so forth.

Contact Now

Crucibles serve as packing containers for samples in the course of thermoanalytical measurements.

Contact Now

Crucibles feature bins for samples sooner or later of thermoanalytical measurements.

Contact Now

Zirconia porcelain ball is a great form of packages of inorganic non-metal grinding medium, specially applied in grinding and dispersion of most important areas, our corporation mainly produces grinding with zirconium balls, especially involved inside the sand mill inner, dispersion is especially concerned in excessive-tempo blending mill internal. zirconia beads are crafted from micron-degree and sub-nano zirconia and yttrium oxide as uncooked substances thru superior era to make diverse technical signs and performance signs to attain the worldwide fashionable diploma.

Contact Now

Magnesia(MgO)crucibles can withstand the high temperature up to 2200°C and has very good resistance to chemical erosions and thermal shock. There is ideal for the melting of precious metals and super-alloys. They possess higher refractory (up to 2000℃ )compared to alumina ceramics , better corrosion resistant to acids and alkalis ,better abrasion resistance. They exhibit fully dense, high strength, extreme wear resistant. , as well as excellent performance in areas of high wear and corrosion for mechanical industry and other high technology applications.

Contact Now

Zirconia porcelain ball is a extensive variety of applications of inorganic non-metallic grinding medium, especially utilized in grinding and dispersion of maximum critical regions, our corporation specifically produces grinding with zirconium balls, in particular involved inside the sand mill internal, dispersion is particularly concerned in excessive-pace blending mill internal.

Contact Now

We've got were given have been given were given effectively provided many specific commonplace merchandise appropriate for the multitudinous customers, espically recognition on researches on small-sizes and complex form alumina elements. we promise a devoted non-public company at low charge, the producing cycle is short, nimble, speedy. no minimum order fee.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

Zirconia porcelain ball is a extensive variety of applications of inorganic non-metallic grinding medium, especially utilized in grinding and dispersion of maximum critical regions, our corporation specifically produces grinding with zirconium balls, in particular involved inside the sand mill internal, dispersion is particularly concerned in excessive-pace blending mill internal.

Contact Now

Zirconia products is in yttria stabilised zirconia. They are either refractory porous crucibles or Zirconia ceramic crucibles.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a fantastic thermal marvel at tempertures to 2000℃, better corrosion evidence in the direction of acids and alkalis ,widely carried out in superalloy and treasured metals industries, on the side of induction melting crucibles for professional metallic, glass melting, treasured and remarkable metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better tha

Contact Now

Crucibles feature bins for samples sooner or later of thermoanalytical measurements.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a superb thermal marvel at tempertures to 2000℃, higher corrosion proof towards acids and alkalis ,widely applied in superalloy and treasured metals industries, at the side of induction melting crucibles for expert steel, glass melting, precious and extraordinary metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina crucible, the use o

Contact Now

Zirconia porcelain ball is a huge kind of applications of inorganic non-steel grinding medium, especially accomplished in grinding and dispersion of most vital areas, our business enterprise enterprise business enterprise mainly produces grinding with zirconium balls, mainly involved inside the sand mill inner, dispersion is specially concerned in excessive-tempo blending mill inner.

Contact Now

Zirconia porcelain ball is a huge variety of packages of inorganic non-metal grinding medium, mainly applied in grinding and dispersion of most critical regions, our business enterprise mainly produces grinding with zirconium balls, in particular involved in the sand mill internal, dispersion is specially involved in immoderate-tempo mixing mill inner. zirconia beads are made from micron-diploma and sub-nano zirconia and yttrium oxide as uncooked substances through superior era to make various technical indicators and performance symptoms to attain the worldwide stylish diploma.

Contact Now

Zirconia porcelain ball is a extensive variety of applications of inorganic non-metallic grinding medium, especially utilized in grinding and dispersion of maximum critical regions, our corporation specifically produces grinding with zirconium balls, in particular involved inside the sand mill internal, dispersion is particularly concerned in excessive-pace blending mill internal.

Contact Now

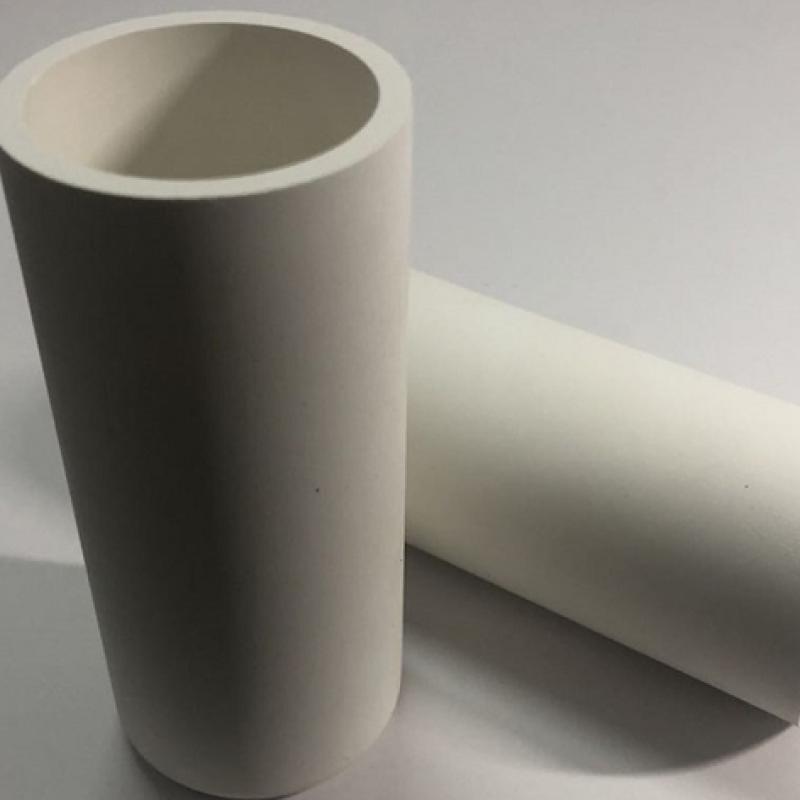

Alumina crucibles are synthetic for extra than 20 years and have a skill manufacturing era in specific shapes and range of sizes from few milliliters to several liters, those absolutely dense, excessive purity and subjected to a temperature of 1700 ℃ , offering resistance in opposition to wear, wash, excessive temperature, has excellent resistance to chemical erosions and thermal shock. together with metallic processing / molten glass, rapid thermal biking, gemstone purification for jewelry industry etc.

Contact Now

Zirconia porcelain ball is a wide range of programs of inorganic non-metallic grinding medium, particularly used in grinding and dispersion of most important regions, our organisation especially produces grinding with zirconium balls, mainly concerned inside the sand mill internal, dispersion is especially involved in excessive-speed mixing mill inner. zirconia beads are made from micron-degree and sub-nano zirconia and yttrium oxide as uncooked substances thru superior generation to make diverse technical indicators and performance signs to reach the global fashionable degree.

Contact Now

We have have been given have been given have been given effectively furnished many particular not unusual merchandise suitable for the multitudinous customers, espically recognition on researches on small-sizes and complex shape alumina elements. we promise a devoted non-public enterprise at low rate, the producing cycle is brief, nimble, rapid. no minimum order charge.SpecificationChemical contentZrO2≥96 wt%CaO3.5 wt% Physical PropertiesMelting point≥2500℃Max.

Contact Now

Zirconia porcelain ball is a tremendous shape of packages of inorganic non-metal grinding medium, specially implemented in grinding and dispersion of maximum important areas, our organization especially produces grinding with zirconium balls, particularly concerned in the sand mill inner, dispersion is in particular concerned in immoderate-tempo mixing mill internal.

Contact Now

Zirconia crucibles have cxcellent chemical inertness and a extraordinary thermal marvel at tempertures to 2000℃, better corrosion evidence in the path of acids and alkalis ,widely executed in superalloy and treasured metals industries, on the aspect of induction melting crucibles for expert steel, glass melting, treasured and exquisite metals melting.Material: Zirconia (Y2O3-FSZ)Specifications;:BTTZ-6840 SIZE:¢6.8X4.0 Wall thickness:0.5mmApply to instruments:GERMANY NETZSCH Zirconia thermal analysis of small crucible fire resistance is better than alumina cr

Contact Now