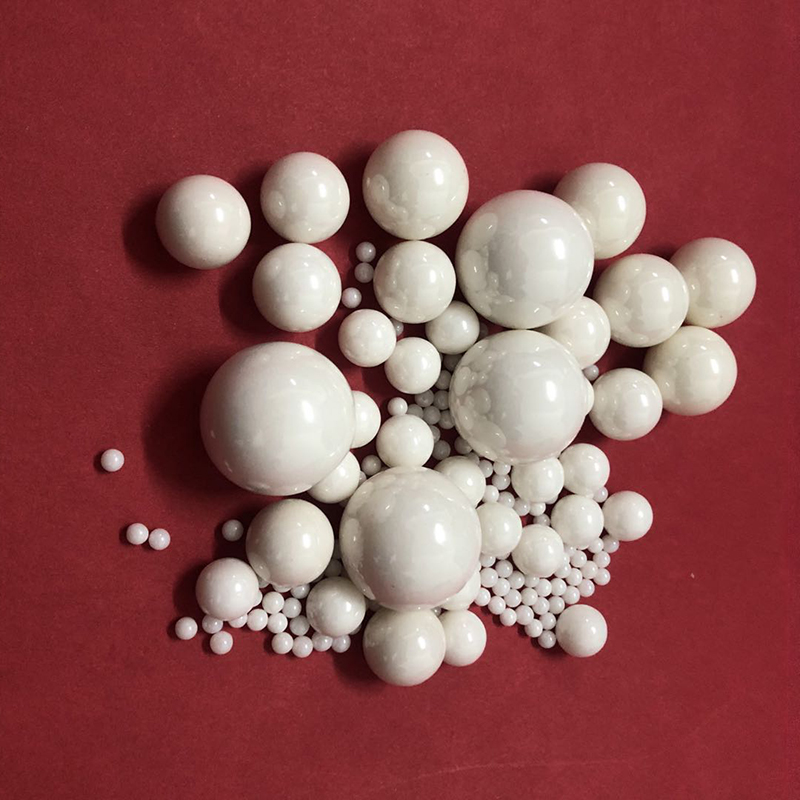

High-purity Alumina Ball

Our company since the production of high efficiency zirconia grinding ball, with high density, high mechanical strength, high dispersion efficiency, low wear consumption, good wear resistance and other characteristics, widely used in non-metallic grinding media, has been a good market verification and the majority of customers push favor. Can be used with our company's production of nylon / polyurethane ball mill tank, there are 1-20mm a variety of particle size products to choose from: ¢2, ¢3, ¢5, ¢8, ¢10, ¢15, ¢20.

Zirconia porcelain ball is a huge variety of applications of inorganic non-steel grinding medium, mainly used in grinding and dispersion of most essential regions, our corporation specially produces grinding with zirconium balls, in particular concerned inside the sand mill internal, dispersion is particularly worried in excessive-velocity mixing mill inner. zirconia beads are made from micron-degree and sub-nano zirconia and yttrium oxide as raw substances via advanced technology to make various technical indicators and performance signs to attain the worldwide stylish diploma. especially utilized in extremely-splendid grinding materials that require "0 pollutants" and high viscosity and immoderate hardness materials.

Specification

Chemical content | ZrO2 | 86wt% |

Y2O3 | 14 wt% | |

Physical Properties | Melting point | ≥2500℃ |

Max. operating temperature | 2000℃ | |

Color | White | |

Density | 5.8g/cm∧3 | |

Mechanical properties | Flexural strength | 200MPa |

Young’s module | 200GPa | |

Hardness(HRA) | 86 | |

Thermal properties | Thermal expansion coefficient(20℃) | 8-10X10∧-6 |

Thermal conductivity | 1-2W/mk | |

Electrical properties | Dielectric constant(1MHz25℃) | 12 |

Electrical resistivity(25℃) | 10∧9 |

Related News

Submitted successfully

We will contact you as soon as possible